Description

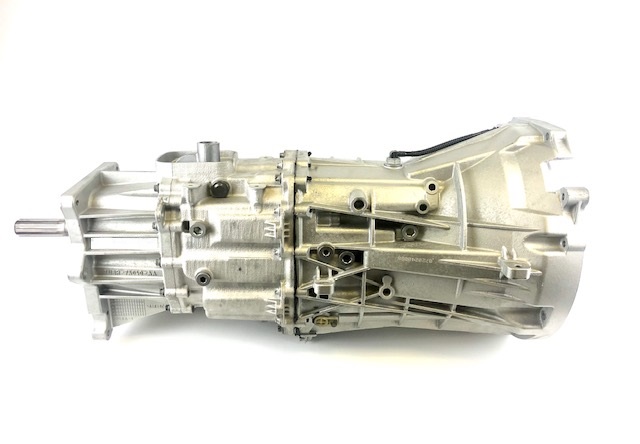

The MT82 6 speed gearbox fitted to the 2.2 and 2.4 TDCi is prone to the spline on the rear output shaft wearing which causes a total loss of drive, this spline ‘frets’ as it is dry in the same way the earlier LT77 and R380 mainshaft splines wear in the transfer case input gear, same thing, different spline.

The MT82 mainshaft comes out of the gearbox and a female/

A male/

The spline that wears is the one at the rear of LR030054 and the front of TUD500020.

We have devised a method to make this splined interface wet with oil which stops the wear.

We make a new coupling (like LR030054) and spark erode two small slits in the front face where it fits to a bearing, also loose two teeth from the front spline at 180 degrees to eachother (to let the oil through), then spark erode another two small slits on the rear face under the clamping bolt, this now allows oil to ‘leak’ out of the mainbox to this spline. We then machine a thread on the outside diameter and also make two O ring grooves.

The new shaft (like TUD500020) has a ground diameter that the transfer case input seals runs on, we machine this diameter further up towards the gearbox for the O rings below) to seal on.

We then make an alloy new part which slides over the shaft, this has 2 ‘O’ rings fitted to the inner diameter which seal on the new ground diameter of the shaft and has both a diameter to seal on the outer coupling O rings and a thread to fit it to the coupling.

A tube spanner is supplied to fit this part.

We are well aware you now have other options from a couple of suppliers to address this output shaft wear issue, my thoughts :

The reason the spline wears is due to excessive misalignment between the MT82 output shaft and the LT230 input gear, this misalignment varies due to the accumulation of tolerances which explains why some cars see regular failures and some dont seen to wear at all. This misalignment causes dry splines faces to rub together under load with each revolution, hence the dry dusty, rusty residue thats visable when inspecting a failure,

Its very hard (if not impossible) to try to correct this misalignment so our design doesnt fight this, it just lubricates the spline to stop the wear, this design is well proven now and we have not had one fail after about 2000 sets sold.

The other options available adopt a different approach, they replace the shaft with a solid item, I cant help but think this would just transfer the stresses from the misalignment to other components possible causing premature wear elsewhere. It just doesnt seem the correct engineering approach to my mind but its your decision !!

David Smith (verified owner) –

Excellent service, fast and well packed delivery. Friendly and very helpful staff.

I have not fitted this upgraded output shaft kit yet but the quality and fitting instructions are excellent.

Highly recommended for fitting to cure the well documented weak point in the Defender output shaft.

Koch Gmbh&Co.KG (verified owner) –

We’ve installed many of these kits in customer vehicles. Everyone is satisfied. It’s the perfect solution for improving the weak point and reducing play in the drivetrain. Well done!

davidlawrence (verified owner) –

Ive fitted a few diffront types but this is by far the best , fast service grate to deal with

Stephan Wolf (verified owner) –

I bought the car used and asked 5 times about the condition of the shaft. Everything was fine, they had never had to replace this shaft, he said. The shaft didn’t last 10k. I had already installed the shaft in a Defender 110 HCPU in 2021 and now in a 110 pickup. I’m sure I’ll be as satisfied as last time.

Greetings from the Weissacher Valley

Rafal Stanny (verified owner) –

I was stuck on which company to go for when choosing this product as there was a few out there but went with Ashcroft as they have being doing it for many of years and even improving there own products over time and so I bought a few things to upgrade my defender as it went in for some work can’t wait to get it back and see the difference with all the parts I used from Ashcroft. Also the customer service team are very helpful, was on the phone to Abbie and even helped with my order being sent out today and called me back to let me know that it was sent. Thank-you

Georgios Tekkis (verified owner) –

We are an independent garage in Cyprus. We recently bought and fitting an upgraded MT82 output shaft kit . Fitting was straight forward and the installation instructions very helpful. Tested the vehicle for about 150 Km ans so far no problem. Customer will do further testing.

Our initial opinion regarding this product is very positive and would recommend it, but further testing is needed to fully assess the product.

4x4development (verified owner) –

fitted 4 of these units now to customers vehicles, all have been easy to fit and give good service. A really good product.

tsnormanltd (verified owner) –

We have fitted many of these kits to different vehicles. They are the perfect way to transform the slack & backlash in the drivetrain. As the outer collar keeps the spline tight the shaft doesn’t move in the first place, so no wear & no slack. It makes gear changing a pleasure.

Chris Dakin –

This kit is now well known to the the best solution to the fast waring factory item. I checked my vehicle details by phone, ordered right away on line and collected next day. Ashcroft kindly recommended two companies in my area for carrying out the installation for me and I was able to arranging fitting that week. Absolutely excellent service from Ashcroft and my Defender is driving better than it ever has done. Brilliant!!!!!!!!!!! I will be back.

Karl (verified owner) –

MT82 Output Shaft Kit

Service and speed of delivery to Australia fantastic!

Great instructions made it easy to install.

A quality product.

Many thanks.

Tony Coates (verified owner) –

Output Shaft Kit.

I have had this drive fail twice in my 2015 110, the first time at 77’000 under warranty, the second at 89’000 that really made me spit, I pulled the back box off and found the coupling in hell of a mess so needed to look for something to put this job to sleep, I thought the Ashcroft upgrade looked a good bet so put in an order over the weekend and had the parts turn up about 8am on the Tuesday morning, the box looked First Rate with the Ashcroft name stamped on it, the parts inside were a delight to look at and the alloy cap again marked up with the Ashcroft name, it is something I like to see as this puts a good thought in my mind that its worthy, included in the box is a short crib sheet on fitting the parts and a lead to picture detail well it all helps, on the crib sheet was a little line on checking the 2 Dowels are in place??? I had NO hollow dowel so this would account for the short life of the L/R dealer fitted parts, I soon bought the hollow Dowel and fitted things back together, the result is the truck fly’s along like it has 50 more bhp, so I am a very happy customer and really pleased with the Service, Parts and Crib Sheet that also has the Ashcroft Name and phone details on if any help is required, as for the price I think it was a Bargain and so pleased to have gone this route.

Tim Freed –

MT82 output shaft kit.

Really good kit with basic instructions on the work needed. Fairly straightforward job to fit. The most difficult bit was welding the bolts to the adapter to slide hammer off. All fitted together perfectly and although I was only carrying out the upgrade for peace of mind it drastically reduced the backlash in the transmission, Even though my splines did not look too bad once removed. For the quality of the engineering involved I think it also represents great value for money. It was the first i have done and Taken me 7 hours to carry out the repair on a 4 post ramp with a pto fitted and a few extra bits to repair along the way.

Marc Missud (verified owner) –

Really good and heavy duty gear

As usual LR told me that the rattle noise coming from my rear diff was normal…replacement of the output shaft by your’s proved the opposit just before breaking down and severe damage. Thank you

George Steel (verified owner) –

Excellent Service

Ordered the out put shaft on a Friday and delivered to my door in Australia on the following Tuesday. Will be fitted along with the ATB Centre Diff on the next service. Expecting great result.

Dan (verified owner) –

Mk82 output shaft kit

Sorry, forgot actual rating

Dan (verified owner) –

Mk82 output shaft kit.

Arrived in Australia at my outback address on Tuesday after only ordering on Friday before!

Awesome service.

Yet to fit, but it looks like a great solution.

Les Malone (verified owner) –

Supply to Australia

Ordered the shaft in Western Australia on the 01/05/2017 arrived 05/05/2017.

Will install when clutch replaced in future.

Les Malone (verified owner) –

MT82 output shaft kit

Ordered on line 1/5/2017 at Perth Western Australia, arrived 5/5/2017. Great service, good bit of kit. To be installed later when clutch fails.

Helmut Käfer –

Third time’s a charm – hopefully!

I fitted the Ashcroft shaft kit when the 2nd original part failed. First shaft lasted 3 years, 41000km, obviously dry assembly. Repaired under warranty, the second shaft was greased and lasted another 3 years, 45000km – In the end, not much grease was left! I hope that the Ashcroft-kit corrects the obvious design flaw and I won’t have to change this da.ned shaft again soon. Will let You know in another 3 years/appr. 40000km!

AW –

Review from downunder

I have a 2013 130 DC as a main work vehicle. Lots of heavy loads and trailers and not very good roads.

At the 40K service I was of the view that the centre shaft between the gearbox and transfer case was starting to wear. More backlash in the system than I would like and the racket was coming from the centre. The expert dealer opinion was that everything was fine.

I thought otherwise and ordered your replacement centre shaft and diff. If the transfer case was coming out then might as well do both at the same time.

At 47K the centre shaft failed. I was right and the dealer expert was wrong.

Under warranty, LR had to transport the vehicle 500km each way – that was the closest dealer – and I got them to install your centre shaft and diff instead of replacing with standard LR bits. Didn’t see much point replacing a shaft which had flogged out at 47K with another identical shaft.

The difference this has made to the vehicle is staggering. There is now absolutely no driveline backlash at all.